Uncover The Ultimate 5Step Guide To Gas Mask Design

In the world of personal protective equipment, gas masks play a crucial role in safeguarding individuals from harmful gases, chemicals, and particles. Designing an effective gas mask involves a meticulous process that considers various factors for optimal performance and user comfort. This comprehensive guide will walk you through the five essential steps to create a gas mask that meets the highest standards.

Step 1: Understanding the Purpose and Requirements

Before embarking on the design journey, it is imperative to clearly define the purpose and specific requirements of the gas mask. Consider the following key aspects:

- Application: Determine the intended use of the gas mask, such as industrial, military, or emergency response.

- Hazardous Agents: Identify the types of gases, vapors, or particles the mask needs to protect against.

- Performance Standards: Research and adhere to relevant industry standards and regulations, such as NIOSH (National Institute for Occupational Safety and Health) or EN (European Norm) certifications.

- User Demographics: Consider the target audience's characteristics, including age, gender, and physical attributes, to ensure a comfortable and secure fit.

Step 2: Selecting the Right Materials

The choice of materials is critical for the effectiveness and durability of the gas mask. Here are some key considerations:

- Mask Body: Opt for high-quality, durable materials like silicone or rubber for the mask's body. These materials provide flexibility, comfort, and resistance to chemicals.

- Filter Media: Select appropriate filter media based on the targeted hazardous agents. Different filters are designed to capture specific types of gases, vapors, or particles.

- Lenses: Choose scratch-resistant and impact-resistant lenses to ensure clear vision and protect against potential hazards.

- Straps and Headgear: Select comfortable and adjustable straps made from breathable materials to distribute weight evenly and provide a secure fit.

Step 3: Ergonomic Design and Fit

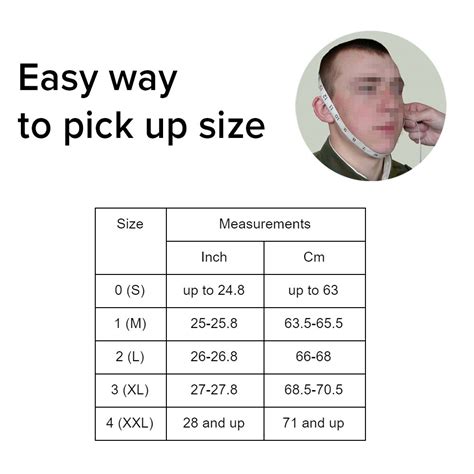

Creating a gas mask that fits comfortably and securely is essential for user acceptance and effectiveness. Here's how to achieve an ergonomic design:

- Facepiece Design: Develop a facepiece that conforms to the natural contours of the face, minimizing gaps and ensuring a tight seal. Consider using adjustable straps and padding for a customizable fit.

- User Testing: Conduct extensive user testing with diverse participants to gather feedback on comfort, fit, and ease of use. This step is crucial for identifying and addressing any design flaws.

- Valve Placement: Strategically position inhalation and exhalation valves to optimize airflow and reduce breathing resistance. Proper valve placement enhances user comfort and efficiency.

Step 4: Incorporating Advanced Features

To enhance the performance and functionality of the gas mask, consider integrating the following advanced features:

- Voice Communication: Implement a communication system that allows users to communicate effectively while wearing the mask. This feature is particularly important for military and emergency response applications.

- Sensor Technology: Integrate sensors to detect and monitor hazardous agents, providing real-time feedback to the user. This adds an extra layer of protection and ensures timely response.

- Breathable Comfort: Design the mask with breathable materials and features that minimize heat buildup and condensation, ensuring a comfortable experience during prolonged use.

Step 5: Testing and Certification

Thorough testing and certification are essential to ensure the gas mask meets industry standards and performs as intended. Follow these steps:

- Laboratory Testing: Conduct rigorous laboratory tests to evaluate the mask's performance against various hazardous agents. This includes testing for filter efficiency, fit, and overall functionality.

- Real-World Scenarios: Test the gas mask in realistic scenarios to simulate actual conditions. This step helps identify any potential issues or limitations that may arise during practical use.

- Certification: Obtain the necessary certifications from recognized bodies, such as NIOSH or EN, to ensure compliance with industry standards and regulations.

By following these five steps, you can design a gas mask that provides optimal protection, comfort, and functionality. Remember, the key to a successful gas mask design lies in understanding the specific requirements, selecting high-quality materials, ensuring a secure fit, and incorporating advanced features for enhanced performance.

What are the key factors to consider when selecting filter media for a gas mask?

+

When choosing filter media, consider the types of hazardous agents you need to protect against. Different filters are designed for specific gases, vapors, or particles. It’s crucial to select filters that have been tested and certified to ensure their effectiveness against the targeted agents.

How can I ensure a secure and comfortable fit for the gas mask?

+

Achieving a secure fit involves careful consideration of the facepiece design and user testing. Develop a facepiece that conforms to various facial shapes and sizes, and use adjustable straps and padding to customize the fit. Conduct extensive user testing to gather feedback and refine the design based on real-world feedback.

What are the benefits of incorporating sensor technology in a gas mask?

+

Integrating sensor technology enhances the overall performance and safety of the gas mask. Sensors can detect and monitor hazardous agents, providing real-time feedback to the user. This allows for prompt response and increased protection, especially in environments with unknown or changing hazards.

How important is user testing in the gas mask design process?

+

User testing is a critical step in the design process as it ensures that the gas mask meets the needs and expectations of its intended users. By gathering feedback from diverse participants, designers can identify and address any design flaws, improve comfort, and enhance the overall user experience.

What are the key considerations for obtaining certifications for a gas mask?

+

To obtain certifications, it is essential to adhere to the relevant industry standards and regulations. This includes conducting thorough laboratory and real-world testing to demonstrate the mask’s performance and effectiveness. Working with recognized certification bodies, such as NIOSH or EN, ensures that the gas mask meets the required safety criteria.